JTW型不锈钢金属软管

上海淞江减震器集团有限公司官方网站为您介绍:JTW型不锈钢金属软管信息,淞江集团为众多管道管线配套不锈钢金属软管产品,主要起到沉降、偏转、弯曲、减震等效果,保护了管道系统的长期安全运行。

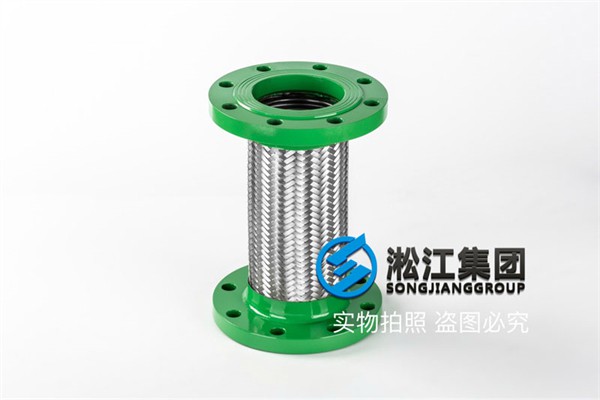

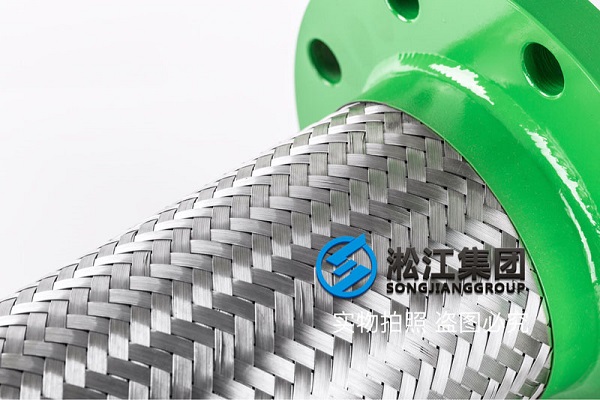

一、JTW型 不锈钢金属软管实物拍照:

二、JTW型不锈钢金属软管介绍:

JTW型不锈钢金属软管(简称软管)是管道系统中一种高品质的柔性管道接头,它主要由波纹管、网套和法兰组成。内管是环形的薄壁不锈钢波纹管,外层的网套是不锈钢丝或钢带按一定的参数编织而成。两端的法兰可以制作固定的或松套的,也可以一端固定,一端松套,方便安装。

由于制作软管主要零件的材料是采用奥氏体不锈钢,因而保证了软管优良的耐温性和耐蚀性,软管的工作温度范围最广,为 -196—600 度,使用的软管按管道所通介质的腐蚀性选择适用的不锈钢牌号,即可保证软管的耐蚀性。

1、金属软管整体采用1Cr18Ni9Ti不锈钢材料制成,具有较强的耐腐蚀能力。

2、软管管体为薄壁不锈钢管体液压成形,具有较强的柔韧性、伸缩性、弯曲和抗振能力强、编织网套的加强保护、使之具有更高的承压能力。

3、软管两端的连接还可制成除螺纹、法兰标准之外的其他连接方式,方便连接和使用。

4、该产品不仅适于与旋转接头的配套,而且广泛用于多种流体介质输送的软性连接。耐腐蚀、耐高温、耐低温,重量轻、体积小、柔软性好。广泛用于航空、航天、石油、化工、冶金、电力、造纸、木材、纺织、建筑、医药、食品、烟草、交通等行业。

四、JTW型不锈钢金属软管优点:

1、金属软管节距之间灵活软管,弯曲半径小。

2、金属软管有较好的伸缩性,无阻塞或僵硬。

3、金属软管单位重量轻、口径一致性好。

4、金属软管柔软性、重复弯曲性、挠性好。

5、金属软管耐腐蚀性、耐高温性好。

6、金属软管防鼠咬、耐磨损好,防止内部电线受到磨损。

7、金属软管耐弯折、抗拉性能、抗侧压性强。

8、金属软管柔软顺滑、易于穿线安装定位。

9、金属软管配套的软管接头多,容易同仪器设备连接。

10、介质要求:请在管道进水口加装有效去除氯离子装置(氯离子含量不超过25mg/L),避免水氯离子含量超标,产生针孔腐蚀;

11、橡胶接头是用在设备进出口的,可以补偿轴向和横向位移,减震效果是最好的。并且不受管道内部介质的腐蚀。

12、金属软管(外面带编织网的)这种可以用在设备进出口,可以起到减震的作用,也可以补偿横向位移,轴向位移很小的。但是要注意介质腐蚀问题。

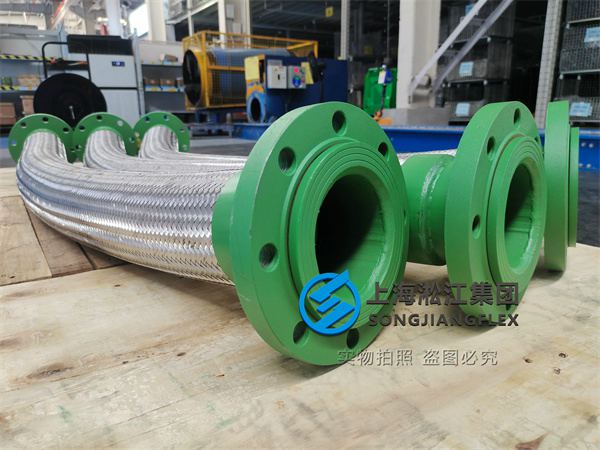

五、JTW型 不锈钢金属软管发货现场:

六、JTW型 不锈钢金属软管光谱检测现场:

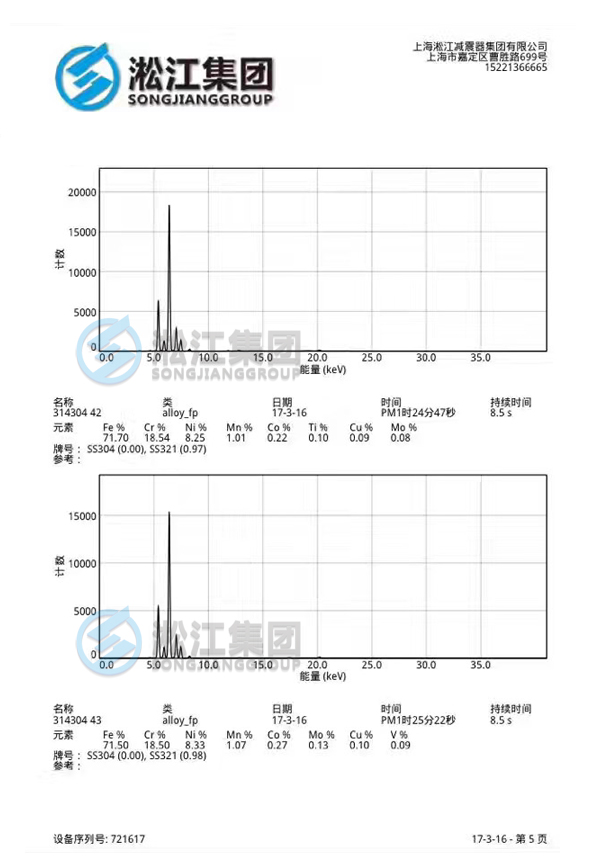

七、JTW型 不锈钢金属软管光谱检测报告:

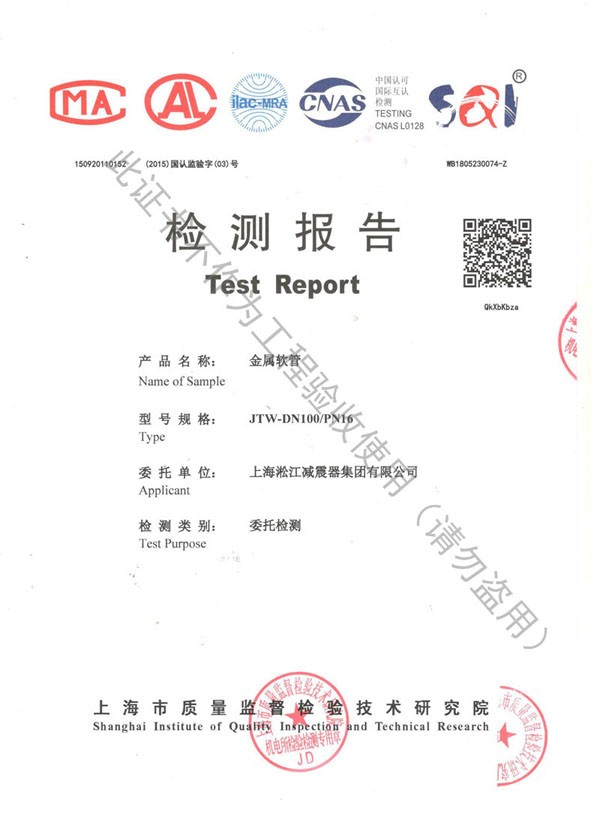

八、JTW型 不锈钢金属软管检测报告:

提示:如需最新版JTW型 不锈钢金属软管检测报告请联系我们。

九、JTW型 不锈钢金属软管使用现场:

十、JTW型不锈钢金属软管链接方式:

1、螺纹式:通径为50毫米以下的金属软管的接头,在承受较高工作压力的情况下,多以螺纹式为主,当拧紧螺纹以后,两个接头上的内、外锥度面紧密配合,实现密封。锥角一般为60度,也有用74度的。该结构密封性好,但安装时必须保证两个对接件的同心度。为了解决实际工程中经常见到的反复拆、装和不易同心等问题,也可以 将接头设计成锥面与球头的配合。

2、法兰盘式:通径为15毫米以上的金属软管的接头,在承受一般工作压力的情况下,以法兰盘式为主,它以密封面配合的形式进行密封。可沿径向转动,也可沿轴向滑动的活套法兰盘在紧固螺栓拉力的作用下连接两体。该结构密封性能良好,但加工难度大,密封面容易碰坏。在需要快卸的特殊场合,可以将固紧螺栓通过的孔划开,制成快卸式法兰盘。

3、快速式:通径为100毫米以下的各种金属软管的接头,在要求快速装卸的使用条件下,一般采用快速式。它常用氟塑料或一种橡胶制成的“O”形密封圈密封。当手把搬动一定的角度以后,相当于多头螺纹的爪指被锁紧;“O”形密封圈被压得越紧,其密封性能越好。该结构在火场、战地及其它必须快装快卸的场合最为适宜。在几秒钟的时间内,不需配用任何专用工具,就可以对接或拆开一组接头。

十一、JTW型 不锈钢金属软管工厂介绍:

相关链接:【上海特斯拉超级工厂】金属软管合同